- 1. Importance of Reliable Suppliers for Tantalum Procurement

- 2. Properties and Applications of Tantalum

- 3. Key Considerations

- 4. How to choose a reliable tantalum supplier

- 5. Challenges and solutions in tantalum sourcing

- 6. Sustainability in tantalum supply chains

- 7. Future trends in tantalum sourcing

- 8. Conclusion

Tantalum is a rare and valuable metal with unique properties. It’s widely used in various industries for its exceptional corrosion resistance and high melting point. If you require a tantalum supply, finding a reliable tantalum supplier is crucial for your procurement needs.

Importance of Reliable Suppliers for Tantalum Procurement

Ensuring a stable tantalum supply chain is essential for industries reliant on this valuable metal. Reliable tantalum suppliers play a crucial role in meeting tantalum supply and demand dynamics. With the increasing demand for tantalum across various sectors, partnering with trustworthy suppliers ensures uninterrupted access to this critical material. Tantalum procurement requires careful consideration of quality, reliability, and ethical sourcing practices, choosing suppliers is a significant factor in successful operations.

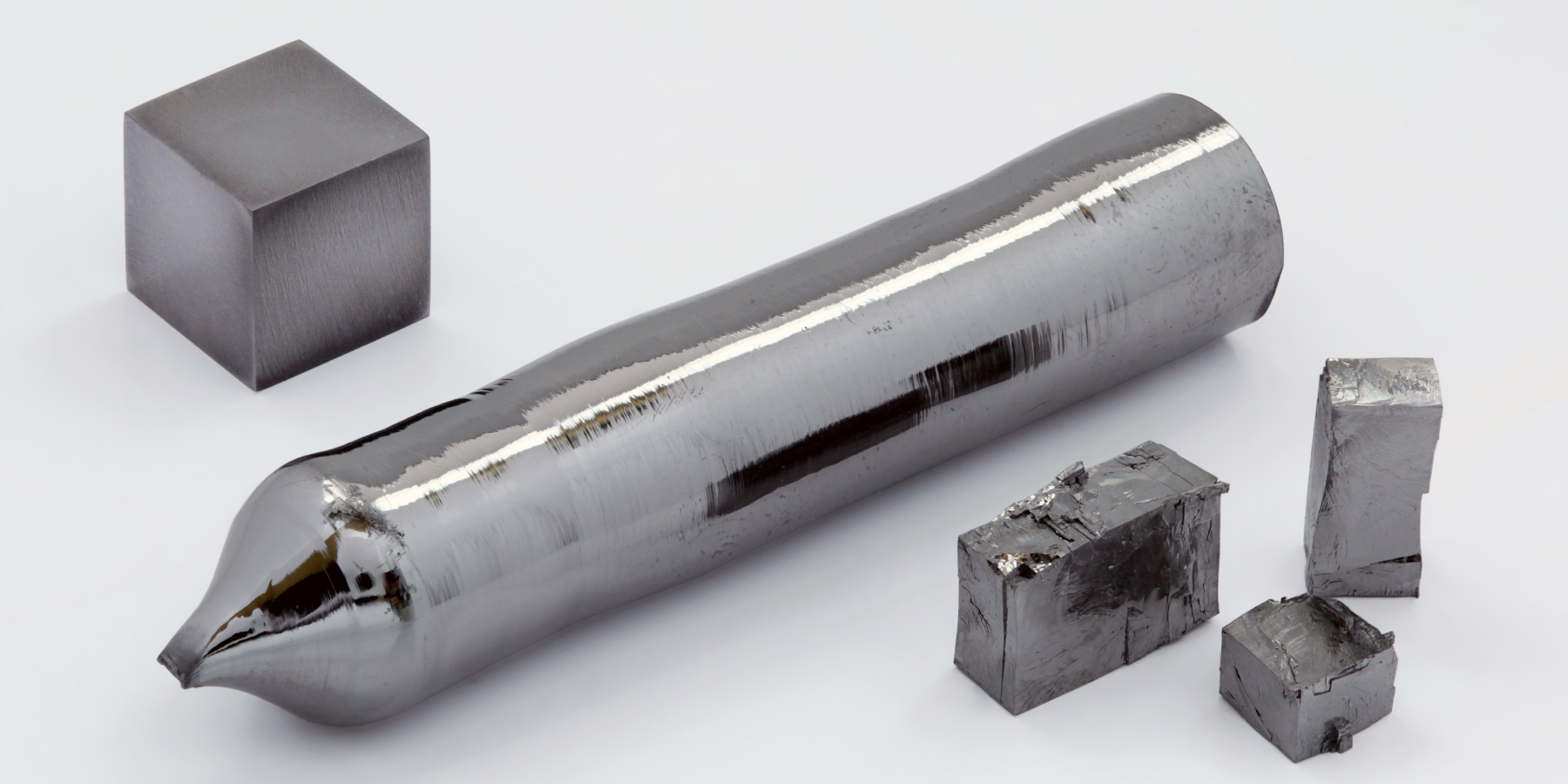

Properties and Applications of Tantalum

Physical and Chemical Properties

Tantalum exhibits remarkable physical and chemical properties, making it highly desirable in various industries. With a high melting point and excellent corrosion resistance, tantalum is a sought-after material for demanding applications. When considering what is tantalum material, its ductility and conductivity further enhance its utility in manufacturing processes.

Diverse Applications of Tantalum

Tantalum finds diverse applications across a wide range of industries, including electronics, aerospace, medical, and more. In the electronics sector, tantalum capacitors are widely used due to their high capacitance and reliability.

- Aerospace applications include turbine blades and structural components, where tantalum’s strength and heat resistance are invaluable.

- Medical implants also utilize tantalum for its biocompatibility and corrosion resistance, ensuring long-term success in the human body.

- With tantalum supply and demand on the rise, reliable tantalum suppliers play a crucial role in meeting the needs of various industries.

Corrosion Resistance

- Tantalum capacitors are favored for their high capacitance and reliability.

- Used in various electronic devices such as smartphones, computers, and automotive electronics.

- Offers stable performance over a wide temperature range, making it suitable for demanding applications.

Aerospace

- Tantalum is utilized in aerospace for turbine blades and structural components.

- Its strength and heat resistance properties make it indispensable for withstanding extreme conditions.

- Enhances the performance and durability of aerospace equipment, ensuring safety and reliability.

Medical

- Tantalum is employed in medical implants due to its biocompatibility and corrosion resistance.

- Ensures long-term success within the human body without adverse reactions.

- Used in orthopedic implants, such as hip replacements, and in dental applications, among others.

More about tantalum

- Tantalum is also used in other industries such as automotive, where it contributes to the efficiency and reliability of various components.

- Its high melting point and corrosion resistance make it valuable in chemical processing equipment.

- Tantalum’s properties also find applications in the production of specialized alloys and superalloys for high-performance engineering.

Key Considerations

Importance of Ethical Sourcing and Conflict-Free Supply Chains

Ethical sourcing of tantalum is crucial to ensure that the material is obtained without contributing to conflicts or human rights abuses in mining areas. Conflict-free supply chains guarantee that tantalum is sourced responsibly, benefiting both local communities and global consumers. When considering where tantalum is used, ethical sourcing practices ensure that the material contributes positively to society and the environment.

Quality Standards and Certifications for Tantalum Suppliers

Tantalum suppliers must adhere to rigorous quality standards and obtain relevant certifications to ensure the integrity and reliability of their products. Quality standards such as ISO certifications guarantee that tantalum materials meet industry requirements for purity, consistency, and performance. Reliable tantalum manufacturers prioritize quality control measures to meet the demands of tantalum supply and demand while maintaining high standards of excellence.

How to Choose a Reliable Tantalum Supplier?

Selecting a dependable tantalum supplier is crucial for ensuring smooth operations and quality products. When considering tantalum supply and demand, several factors should be taken into account to make an informed decision.

Factors to Consider Reputation, Experience, Certifications, and Compliance

Reputation speaks volumes about a tantalum supplier’s reliability and trustworthiness in the industry. Experience demonstrates a supplier’s knowledge and capability to meet diverse customer needs. Certifications and compliance with industry standards ensure the quality and ethical sourcing of tantalum materials. When evaluating potential tantalum manufacturers, these factors play a key role in determining the best supplier for your specific requirements.

Challenges and Solutions in Tantalum Sourcing

Addressing Supply Chain Transparency Issues

Ensuring transparency in the tantalum supply chain is essential for ethical sourcing and sustainability. Reliable tantalum suppliers implement measures such as traceability systems and audits to track the origin of tantalum materials and ensure responsible mining practices. By promoting transparency, stakeholders can make informed decisions regarding tantalum supply and demand, fostering a more sustainable supply chain.

Mitigating Risks Associated with Geopolitical Instability and Market Fluctuations

Geopolitical instability and market fluctuations pose significant risks to tantalum manufacturers and consumers alike. To mitigate these risks, diversification of supply sources and strategic inventory management are essential. Additionally, fostering long-term partnerships with reliable tantalum suppliers helps build resilience against geopolitical uncertainties and market volatility. By proactively addressing these challenges, stakeholders can ensure a stable and sustainable tantalum supply chain for years to come.

Sustainability in Tantalum Supply Chains

Initiatives for Responsible Mining and Environmental Stewardship

Responsible mining practices, supported by tantalum suppliers, aim to minimize environmental impact and promote the well-being of local communities. By adhering to strict regulations and implementing sustainable initiatives, such as reforestation and water conservation projects, the tantalum industry strives to mitigate its environmental footprint. These efforts contribute to the long-term viability of tantalum supply and demand while preserving natural resources for future generations.

Impact of Sustainable Practices on Supplier Selection

Incorporating sustainable practices into supplier selection criteria is becoming increasingly important for tantalum manufacturers seeking to meet ethical and environmental standards. Suppliers that prioritize sustainability initiatives, such as ethical sourcing, carbon footprint reduction, and community engagement, are preferred choices. By aligning with environmentally responsible tantalum suppliers, manufacturers can enhance their brand reputation and contribute to a more sustainable future.

Future Trends in Tantalum Sourcing

Emerging Technologies and Applications Driving Demand

As technological advancements continue to evolve, new applications for tantalum are emerging across various industries. These include advancements in electronics, such as smartphones and electric vehicles, where tantalum capacitors are essential components. The increasing demand for tantalum in these sectors presents opportunities and challenges for tantalum suppliers to meet the growing tantalum supply and demand.

Innovations in Tantalum Extraction and Processing

Innovations in tantalum extraction and processing techniques are driving efficiency and sustainability in the supply chain. Sustainable extraction methods, such as hydrometallurgical processes and recycling, are gaining prominence. These innovations not only reduce environmental impact but also ensure a stable and reliable tantalum supply for manufacturers. As the industry continues to innovate, tantalum suppliers must adapt to meet the evolving needs of tantalum manufacturers and end-users.

In conclusion, the sourcing of tantalum involves various challenges and considerations, from ethical mining practices to supply chain transparency. It’s essential to prioritize sustainable sourcing by partnering with reputable tantalum suppliers who adhere to responsible mining and environmental stewardship. By working together with ethical suppliers, stakeholders can ensure a sustainable and reliable tantalum supply chain for the future.

FAQ

Tantalum is mainly used in the electronics industry for capacitors and high-power resistors due to its high capacitance and stability.

The five main uses of tantalum include electronics manufacturing, aerospace applications, medical implants, chemical processing equipment, and superalloys for turbine blades.

The price of tantalum per kilogram varies depending on factors such as purity, market demand, and supply chain dynamics.