Best 2507 Super Duplex Stainless Steel Round Bar Solutions

What is Super Duplex 2507 Stainless Steel?

Super Duplex 2507 is a ferritic-austenitic stainless steel alloy with a high chromium, molybdenum, and nitrogen content. These attributes make it exceptionally resistant to pitting, crevice corrosion, and stress corrosion cracking, even in the harshest environments.

Key Features:

- Yield Strength: Double that of standard austenitic stainless steel.

- Corrosion Resistance: Superior performance in chloride-rich environments, such as seawater and chemical plants.

- Thermal Stability: Effective in extreme temperature variations.

- Weldability: Allows for seamless integration into complex structures.

Applications of 2507 Super Duplex Stainless Steel Round Bars

1. Oil and Gas Industry

- Why It’s Used:

High resistance to corrosion in offshore and subsea environments.- Applications: Drill collars, risers, and offshore platforms.

2. Chemical Processing

- Why It’s Used:

Handles highly corrosive acids, alkalis, and salt solutions.- Applications: Heat exchangers, pressure vessels, and piping systems.

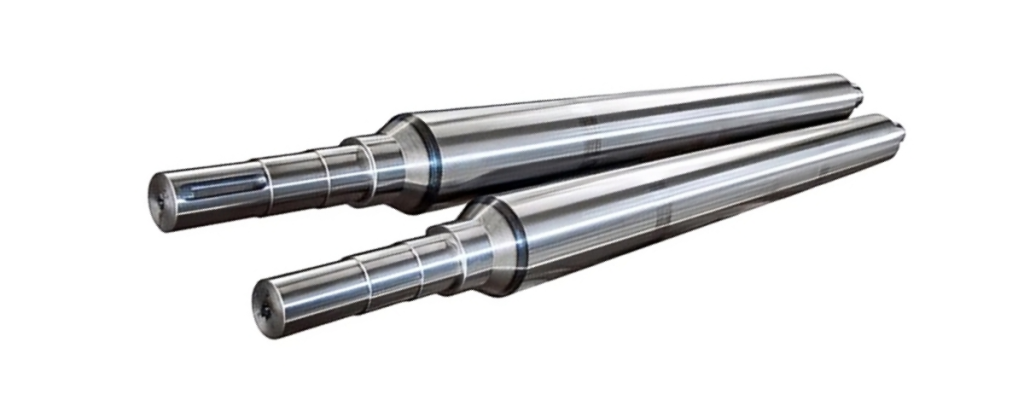

3. Marine Industry

- Why It’s Used:

Exceptional resistance to seawater corrosion and biofouling.- Applications: Marine shafts, propeller rods, and structural components.

4. Power Generation

- Why It’s Used:

High mechanical strength and thermal stability in demanding environments. - Applications: Turbine components, boilers, and heat exchangers.

Benefits of 2507 Super Duplex Round Bars

- Exceptional Corrosion Resistance:

With high chromium and molybdenum content, 2507 round bars can withstand aggressive chemical and saline environments. - High Strength-to-Weight Ratio:

Ideal for applications requiring durable yet lightweight materials. - Cost-Effective:

Reduces material thickness without compromising performance, lowering overall project costs. - Longevity:

Offers a longer lifecycle compared to other steel types, minimizing maintenance and replacement costs.

How to Choose the Right Super Duplex 2507 Round Bar Supplier

When sourcing Super Duplex Stainless Steel round bars, consider the following factors:

1. Material Certification

- Ensure the supplier provides certifications like ASTM, ASME, or EN standards to verify quality.

2. Customization Options

- Look for suppliers offering custom diameters and lengths to suit specific project needs.

3. Surface Finish

- Choose between polished, heat-treated, or pickled finishes based on the application.

4. Delivery and Support

- Opt for suppliers with reliable delivery timelines and robust customer support.

Super Duplex 2507 vs. Other Stainless Steels

| Property | 2507 Super Duplex | 316 Stainless Steel | 2205 Duplex Steel |

|---|---|---|---|

| Yield Strength | 2x higher than 316 | Moderate | Slightly lower than 2507 |

| Corrosion Resistance | Exceptional in chloride-rich environments | Good, but limited to mild conditions | Very good, but less than 2507 |

| Cost Efficiency | High, due to reduced thickness | Moderate | Higher initial cost, good ROI |

| Applications | Offshore, chemical, marine | General purpose | Moderate industrial use |

Conclusion

Super Duplex 2507 stainless steel round bars are a game-changer for industries needing durable, corrosion-resistant, and high-strength materials. From offshore platforms to chemical processing plants, their versatility and performance make them an excellent choice for challenging applications.

Looking for premium Super Duplex 2507 round bars? Contact a trusted super duplex stainless steel supplier today to explore high-quality solutions tailored to your needs.

FAQ

Its high resistance to pitting and crevice corrosion, coupled with excellent mechanical strength, makes it perfect for use in harsh marine environments.

Super Duplex 2507 has higher chromium, molybdenum, and nitrogen content, providing superior strength and corrosion resistance compared to standard duplex grades.

Yes, most reputable suppliers offer custom diameters, lengths, and finishes to meet specific project requirements.