Industrial Valve Components: A Complete Guide

In sectors like oil and gas, power generation, water treatment, and chemical processing, valves are crucial for managing the flow of liquids, gases, and slurries. Every valve is made up of components that define its durability, safety, and function. Engineers and purchasers can select the best valve for their applications by being aware of these factors. The main parts of industrial valves will be dissected in this guide, along with differences between globe, safety, butterfly, and gate valve components.

Why Valve Components Matter?

Every component of a valve plays a part in its operation, from withstanding corrosive environments to sealing against pressure. Selecting the incorrect design or material might result in:

- Inefficiency in operations and leakage

- Early deterioration and breakdown

- Increased expenses for upkeep

You may guarantee dependability and adherence to industry standards by making well-informed selections by learning about valve components.

Key Industrial Valve Components

Although each type has a different design, the majority of industrial valves consist of:

- Body: The valve’s primary shell that retains pressure.

- The stem is housed and sealed by the bonnet, which is attached to the body.

- Stem: Attaches the handwheel or actuator to the plug or disc.

- The moving component that controls flow is the disc, plug, or ball.

- Seat: Offers an impenetrable barrier between the disc and the body.

- Handwheel/actuator: Enables automatic or manual operation.

- Gaskets and packing: provide leak-proof operation under stress.

Gate Valve Components

Gate valves are widely used where full open or full shutoff is required.

Common gate valve components include:

- Body & Bonnet: Usually cast steel or stainless steel for strength.

- Gate/Disc: Slides up and down to stop or allow flow.

- Stem: Moves the gate via rising or non-rising stem designs.

- Seat Rings: Hard-faced surfaces ensuring tight shutoff.

- Handwheel/Actuator: For manual or powered control.

Applications: Pipelines, oil refineries, and water distribution networks.

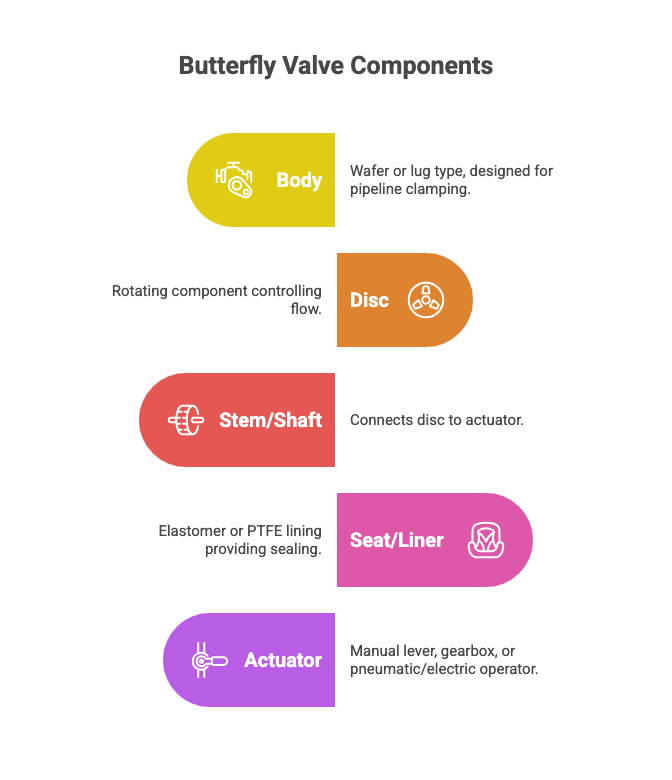

Butterfly Valve Components

Butterfly valves are lighter and more compact, suitable for quick shutoff and throttling.

Key butterfly valve components:

- Body: Typically wafer or lug type, designed for pipeline clamping.

- Disc: Rotating component (like a butterfly wing) controlling flow.

- Stem/Shaft: Connects disc to actuator.

- Seat/Liner: Elastomer or PTFE lining providing sealing.

- Actuator: Manual lever, gearbox, or pneumatic/electric operator.

Applications: HVAC systems, chemical plants, water treatment facilities.

Safety Valve Components

Safety valves protect equipment from overpressure, making them critical in boilers and pressure vessels.

Safety valve components include:

- Body: Withstands high pressure and temperature.

- Spring: Preloaded to a set pressure; lifts when pressure exceeds limits.

- Disc/Nozzle: Rises to release excess fluid or steam.

- Spindle/Stem: Transmits force from spring to disc.

- Bonnet & Lever: Provides external control and enclosure.

Applications: Boilers, compressors, chemical reactors, and storage tanks.

Globe Valve Components

Globe valves are designed for throttling and regulating flow.

Main globe valve components include:

- Body: Typically spherical with an internal baffle.

- Disc/Plug: Moves perpendicular to flow to regulate.

- Stem: Raises or lowers disc precisely for control.

- Seat: Provides sealing when the disc is closed.

- Bonnet: Holds packing and guides the stem.

- Handwheel/Actuator: Allows manual or automated adjustment.

Applications: Power plants, chemical process systems, and cooling water lines.

Material Selection for Valve Components

The performance of valves depends not only on design but also on material choice. Common materials include:

- Carbon steel: High strength, general service.

- Stainless steel: Corrosion-resistant, ideal for aggressive media.

- Bronze/Brass: Good corrosion resistance, often used in marine service.

- Alloys (Hastelloy, Inconel): Excellent resistance to acids and high temperatures.

Conclusion

Choosing the appropriate valve for industrial processes requires an understanding of the components of the valve. Every component of a valve, whether it be a globe valve for precise throttling, a safety valve for pressure protection, a butterfly valve for compact flow control, or a gate valve for pipelines, is essential to system dependability. Long-term effectiveness and safety are guaranteed by careful material and design selection.

FAQ

The essential valve components include the body, bonnet, stem, disc or plug, seat, and actuator, which together regulate flow and pressure.

Gate valve components include a body, bonnet, stem, gate/disc, seat rings, and actuator.

Materials include carbon steel, stainless steel, bronze, and specialty alloys like Inconel and Hastelloy, chosen based on operating conditions.

The disc and liner/seat design allows quick shutoff and compact installation, ideal for large pipelines.

Safety valve components protect boilers, compressors, and reactors by releasing excess pressure automatically.