Why Is SS 316 Stainless Steel Best for Marine Use?

Among the most reliable materials for industries that work in extremely corrosive conditions are hastelloy alloys. These nickel-based alloys are extensively utilized in chemical processing, pollution management, and maritime engineering because of their exceptional resistance to oxidising and reducing chemicals. Two of the most frequently stated grades among them are Hastelloy C22 and Hastelloy C276. However, how can you choose the one that best fits your application? To assist you in making an informed decision, this guide examines the two alloys, their characteristics, and practical uses.

What Are Hastelloy Alloys?

Nickel, chromium, molybdenum, and iron make up the majority of hastelloy alloys, which are metal materials that resist corrosion. Strong oxidisers, reducing agents, and chloride-rich conditions are only a few of the harsh circumstances that these alloys are made to endure.

Each grade in the family, such as Hastelloy alloy B-2, Hastelloy C276, and Hastelloy C22, is tailored for a particular environment.

Hastelloy C22: Properties and Applications

Superior resistance to saltwater and chlorides is one of SS 316’s primary characteristics.

- resists corrosion in crevices and pitting.

- holds up well in both hot and cold temperatures.

- Surface that doesn’t react (clean and sanitary)

Why Does SS 316 Outperform Other Stainless Steel Products?

The nickel, chromium, and molybdenum alloy Hastelloy C22 is made to be as resistant to oxidising conditions as possible.

Crucial Elements of Hastelloy C22:

- strong defence against oxidising agents such as cupric and ferric chlorides.

- robust protection against nitric acid and moist chlorine.

- outstanding formability and weldability.

Typical Uses:

- Equipment for chemical processing

- Scrubbers for flue gases

- Systems for bleaching pulp and paper

Hastelloy C276: Properties and Applications

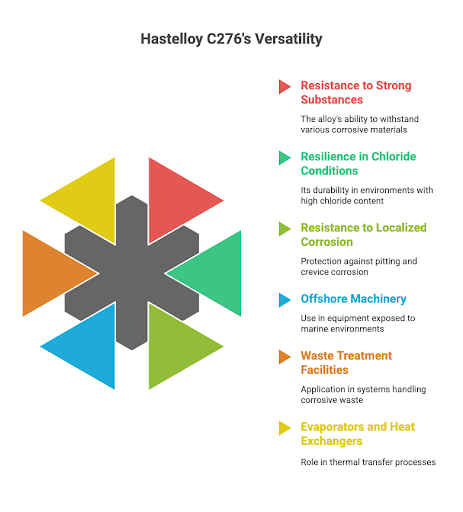

Among the Hastelloy family, Hastelloy C276 is regarded as the “workhorse.” It is well-known for its adaptability and works effectively in both reducing and oxidising environments.

Crucial Elements of Hastelloy C276:

- exceptional resistance to a variety of strong substances.

- remarkable resilience in conditions contaminated with chloride.

- resistant to pitting and crevice attack, two types of localised corrosion.

Typical Uses:

- Offshore machinery and marine engineering

- Facilities for treating waste

- Evaporators and heat exchangers

Other Benefits of SS 316 Beyond Marine Environments

Although its most common use is in the maritime industry, SS 316 is also preferred in pharmaceuticals: Because of its sanitary qualities;

- Surfaces used in food processing that are non-reactive and easily cleaned

- Chemical plants: Able to withstand solvents and acids

- Because of its adaptability, SS 316 is among the most valued steel products in the world.

Conclusion

SS 316 stainless steel is superior to SS 304 and SS 410 when it comes to steel goods intended for marine applications. Because of its molybdenum-enriched composition, SS 316 is resistant to pitting, corrosion, and crevice attack in seawater, guaranteeing durability in challenging marine environments. SS 316 is the wise, long-term investment for desalination plants, offshore rigs, and shipbuilding.

FAQ

Hastelloy alloys are nickel-based materials with chromium, molybdenum, and iron. This composition gives them strength and corrosion resistance in aggressive environments.

It depends on the application. Hastelloy C22 is best for oxidizing conditions, while C276 provides versatile protection in both oxidizing and reducing environments.

Hastelloy alloy B-2 excels in reducing environments like hydrochloric acid and hydrogen chloride gas, but it is not recommended for oxidizing conditions.

They offer exceptional corrosion resistance, high strength, and durability in environments where stainless steel or other alloys would fail.

C22 is used in chemical processing, scrubbers, and bleaching systems. C276 is common in marine engineering, waste treatment, and heat exchangers.