Why Nickel Aluminium Bronze is the Go-To Alloy for Corrosion-Resistant Applications?

In this guide, we’ll break down what is Nickel Aluminium Bronze, its chemical properties, comparisons with other Monel materials and industrial applications

Nickel aluminium bronze is a versatile and high-performance alloy renowned for its exceptional resistance to corrosion, making it the material of choice for numerous industrial applications. Its combination of nickel, aluminium, and copper results in an alloy that excels in harsh environments, particularly where resistance to seawater, acidic conditions, and high wear is essential. In this blog, we will explore the composition of nickel aluminium bronze, its key benefits, and the casting process that makes it ideal for use in a wide range of applications.

What is Nickel Aluminium Bronze?

Nickel aluminium bronze is an alloy primarily made up of copper, nickel, and aluminium, with small amounts of other elements like iron and manganese. This combination gives the alloy its strength, durability, and excellent corrosion resistance, particularly in marine environments. The addition of nickel and aluminium enhances the alloy’s resistance to oxidation, wear, and fatigue, making it an ideal choice for critical applications.

The nickel-aluminium bronze alloy typically contains around 5-11% nickel, 3-5% aluminium, and a small percentage of iron and manganese. These components work together to provide the alloy with superior mechanical properties and resistance to various environmental factors.

Nickel Aluminium Bronze Composition

The composition of nickel aluminium bronze is key to its superior properties. Here’s a breakdown of the main elements in the alloy:

- Nickel (5-11%): Nickel enhances the bronze’s strength, wear resistance, and resistance to corrosion, particularly in seawater and acidic environments.

- Aluminium (3-5%): Aluminium helps improve the alloy’s strength and adds to its ability to withstand oxidation, particularly in high-temperature environments.

- Copper (balance): Copper is the base metal in nickel aluminium bronze, providing the alloy with its fundamental properties and overall structure.

- Iron and Manganese: Small amounts of iron and manganese improve the alloy’s strength and resistance to pitting corrosion and stress cracking.

This unique combination of elements gives nickel aluminium bronze its ability to perform well in corrosive, high-stress environments, making it an ideal choice for industries such as marine, aerospace, and chemical processing.

Durability: Which Alloy is More Durable?

Both Alloy X-750 and Inconel Alloy X-750 are designed to endure extreme environments, but Inconel Alloy X-750 offers superior durability in applications exposed to higher temperatures and stresses. The additional elements like titanium and aluminium in Inconel Alloy X-750 enhance its resistance to thermal fatigue and oxidation, making it more durable in high-performance environments, such as aerospace and nuclear reactors.

Alloy X-750, while still highly durable, is best suited for moderately high-temperature applications and is often used in power generation and chemical processing where thermal stability is crucial, but not as extreme as in aerospace.

Why Nickel Aluminium Bronze is Ideal for Corrosion-Resistant Applications?

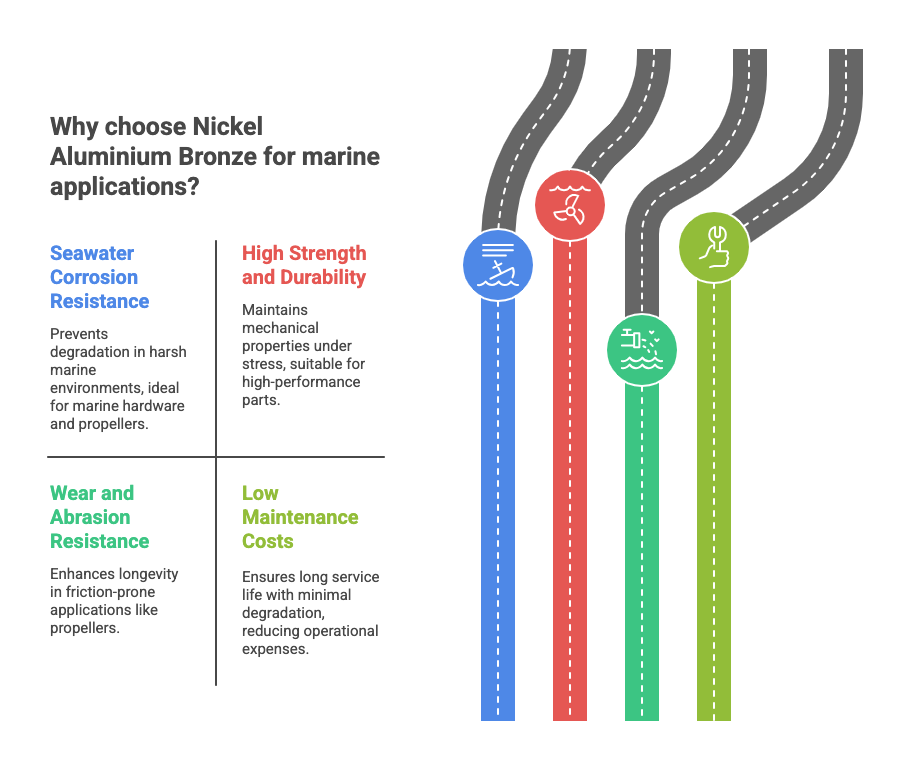

- Excellent Resistance to Seawater Corrosion

One of the primary reasons nickel aluminium bronze is favored in marine applications is its exceptional resistance to seawater corrosion. Unlike traditional metals, this alloy does not easily succumb to the corrosive effects of saltwater. This makes it the preferred choice for marine hardware, propellers, and valves exposed to harsh, saline environments. - High Strength and Durability

Nickel aluminium bronze is known for its outstanding strength and durability. The alloy maintains its mechanical properties under high stress, which is why it’s used for high-performance parts such as propellers, ship components, and pumps in the maritime industry. It can withstand heavy loads and constant movement without losing its structural integrity. - Resistance to Wear and Abrasion

The addition of nickel and aluminium enhances the wear resistance of this alloy, making it an excellent choice for parts exposed to friction. It’s ideal for applications like marine propellers, where constant movement in water can cause other materials to degrade over time. - Low Maintenance Costs

Nickel aluminium bronze has a long service life with minimal degradation, which reduces maintenance costs in industries such as marine and offshore oil rigs. This alloy’s resistance to corrosion, pitting, and fatigue ensures that the equipment lasts longer, which is critical in high-cost operations like subsea equipment and chemical plant components.

Nickel Aluminium Bronze Casting: The Process and Benefits

Nickel Aluminium Bronze Casting: The Process and Benefits

Nickel aluminium bronze casting is the process of forming this alloy into complex shapes, typically using molds to create parts like marine propellers, valves, and seawater pumps. The casting process involves melting the alloy and pouring it into molds that are designed to shape the metal into the desired component.

- Casting Process: The alloy is melted at high temperatures (around 1100°C) and poured into sand or metal molds. After cooling, the casted parts are inspected for any defects or cracks. The casting process allows manufacturers to create intricate shapes that would be difficult or impossible to achieve with other methods.

- Benefits of Casting: The casting process for nickel aluminium bronze offers several advantages, including the ability to produce high-quality, complex parts with tight tolerances. This makes it particularly useful in the marine industry, where components like propellers and flanges need to be both strong and resistant to harsh conditions.

Applications of Nickel Aluminium Bronze

- Marine Industry

Nickel aluminium bronze is widely used for marine applications due to its resistance to corrosion and wear. Common uses include ship propellers, pumps, valves, and seawater intakes. The material’s ability to resist corrosion in saltwater makes it essential for long-lasting and durable components in the maritime sector. - Aerospace and Aviation

In aerospace, nickel aluminium bronze alloy is used for aircraft components that need to withstand high-stress environments and extreme temperatures. Its strength and corrosion resistance make it ideal for parts like landing gears, turbine blades, and aircraft structural components. - Chemical Processing

The alloy is resistant to corrosion in acidic environments, making it suitable for chemical processing plants. Nickel aluminium bronze is commonly used in equipment such as valves, tanks, and piping systems that handle corrosive chemicals. - Offshore Oil and Gas

Components such as pumps, flanges, and marine risers in offshore oil rigs are often made from nickel aluminium bronze to ensure durability and resistance to the harsh marine environment.

Conclusion

Nickel aluminium bronze is a versatile and corrosion-resistant alloy ideal for applications in marine, aerospace, and chemical processing industries. Thanks to its unique composition of nickel, aluminium, and copper, it offers exceptional resistance to seawater, wear, and high-stress environments. Whether it’s used for marine propellers, chemical plant valves, or offshore oil rig components, nickel aluminium bronze provides the durability and performance needed to withstand the harshest conditions.

FAQ

The primary benefit is its outstanding resistance to seawater corrosion, making it ideal for parts exposed to saltwater, such as marine propellers and pumps.

Nickel aluminium bronze provides superior resistance to corrosion, particularly in marine and chemical processing environments, making it more durable than many other materials in similar applications.

Yes, nickel aluminium bronze can be welded, though it requires specific techniques and careful preparation to prevent defects and maintain its corrosion resistance.

Yes, nickel aluminium bronze can withstand high temperatures, making it suitable for applications in aerospace and chemical processing industries that involve heat exposure.

The casting process involves melting the alloy and pouring it into molds to create parts like marine propellers and seawater pumps, providing high-quality, durable components.